Thread forming screws/bolts

A cost-effective solution

Thread forming screws are screws that form an internal, metric, thread in plain holes in ductile metals upon initial installation. The use of thread forming screws reduces the cost of the joint by eliminating the need to thread the mating component prior to assembly.

Trilobular shape

Thread forming screws are typically based on a trilobular shape (the thread is not round), which allows the fastener to form a female metric thread in the mating component during assembly. An advantage of such a female thread is that it becomes stronger and also has a tight fit to the bolt, creating a reliable joint for e.g vibrations.

Types

TAPTITE®

DuoTAPTITE®

TAPTITE® 2000

FASTITE®

TAPTITE® - industry leading thread-forming

TAPTITE® is the registered trademark name of the dominant thread forming screw on the market and is still the leading type of thread forming screw sold today. Bulten is proud to be one of the larger/major licensees of Taptite products in the world and we offer various TAPTITE® products in all size up to M20.

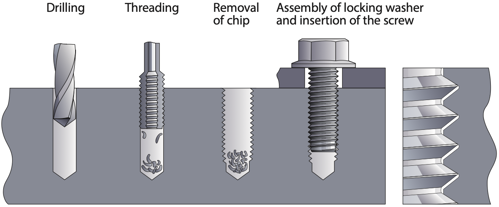

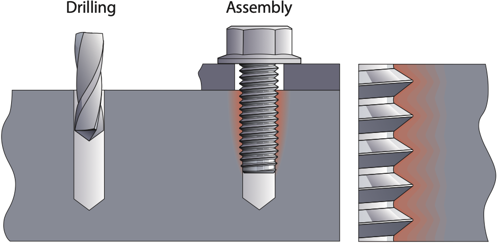

Two methods of forming threads

There are two methods of forming threads in material and assembling screw joints. The conventional method is to assemble the screw into an already tapped hole, where the clearance between the internal and external threads could cause the screw to loosen if subjected to vibration.

The thread-forming method, however, allows the screw to form its own thread in the untapped hole.

The conventional method

The thread-forming method

TAPTITE 2000®

TAPTITE 2000® fasteners provide end users with enhanced opportunities to reduce the total cost of assembly. TAPTITE 2000® thread forming technology combines two unique concepts to improve fastener performance.

TAPTITE 2000® fasteners are designed to provide the benefits of previous TAPTITE® fastener products with an innovative new thread design – the Radius Profile™ thread.

TAPTITE 2000®

TAPTITE 2000® “SP”TM

Other types of TAPTITE®

Other types of TAPTITE® are TAPTITE ii® and DUO-TAPTITE®, which are widely used within the industry.

While TAPTITE ii® screws have a constant trilobularity throughout the whole threaded section, DUO-TAPTITE® screws have a larger trilobularity at the end of the screw, partly to help the screw enter the hole, and partly to give the thread better thread-forming ability. In addition, a stabilizing thread dog tip ensures fast, aligned entry, with easy pickup, requiring minimal initial axial force.

These two types of TAPTITE® form the basis of the TAPTITE 2000® design.

TAPTITE II®

DUO-TAPTITE®