Self-aligning screws/bolts

Reduce cross-threading problems

Self-aligning screws are screws with a tip/end design that is intended to locate the mating hole and align the screw to the mating threads, thereby reducing the risk for cross-threading. Bulten can offer several different types of extended tips, in order to solve different types of assembly problems.

Extended tips to solve assembly problems

Extended ends are designed to locate the mating hole and align the screw with the mating thread, reducing the risk of cross-threading. An extended end is an invaluable feature for assemblies where operator visibility or access is limited.

Depending on the application, several different extended ends are available to solve different assembly problems.

Dog Point

The most common extended end is called Dog Point if it is included in the screw's nominal length. If not, the correct name is Pilot Point. The diameter is reduced slightly below the thread root diameter. It's used to facilitate alignment with the mating nut part. Reference standard is ISO 4753.

Pilot Point

The Pilot Point with truncated cone (PC) is primarily used to locate the hole when the clearance hole is not aligned with the nut member. Reference standard is ISO 4753.

CA-Point

The CA-Point is a gimlet point that is used when the clearance hole and the nut part are not in line.

BUFO®

The BUFO® Grip allows a one-way assembly with a stem fixating the screw while the nut is tightened.

Types

MAThread

Dog point

Pilot point

CA-point

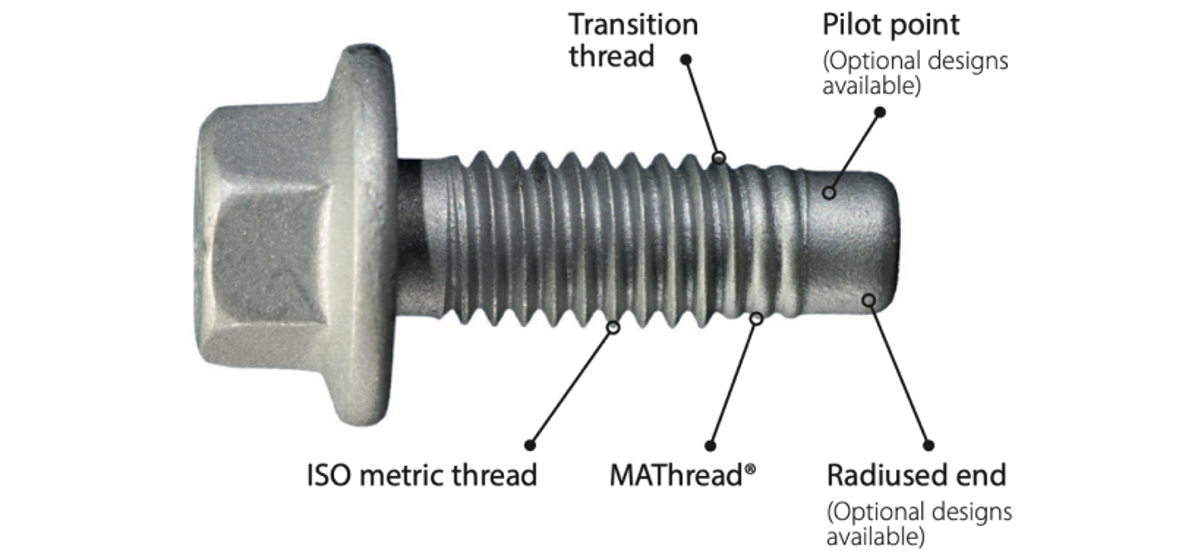

MAThread®

MAThread® was introduced in the mid 1990’s and has since then become a standard in the automotive industry. It has a unique design of thread inlet and dog point tip.

The MAThread® design consists of the following features:

- A Pilot point, which aligns the bolt to the nut axis and aligns the components being joined.

- MAThread®, which supports the bolt to roll over incomplete threads.

- Transition thread, a transition from the MAThread® to a standard ISO metric thread.

Benefits of using MAThread®

The MAThread® fastener eliminates cross-threading and jamming, and also provides several other benefits including:

- Corrects off-angle installations and forces component alignment without thread damage.

- Eliminates hand start.

- Overcomes weld splatter in weld nuts.

- Overcomes excess paint in mating nut threads.

- Is not sensitive to assembly tool speed.

How it works

Axis alignment

The versatile MAThread® design allows the user to select the most appropriate point shape for the application.

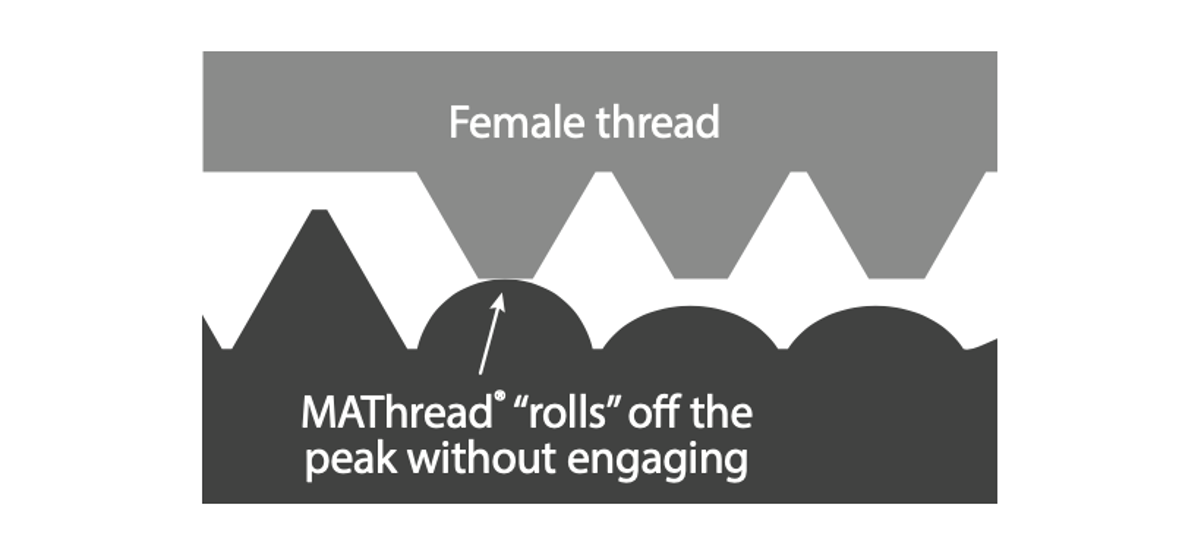

Thread cam into alignment

As the threads come into contact the anticross thread, MAThread®, begins to cam over the female thread.

Thread drive normally

The MAThread® forces the two thread helixes to align. The fastener then drives easily, with reduced effort.

MAThread® versions

MATpoint®

For use in most applications.

DOG POINT MAThread®

For use in any very difficult application or when prying components into place during installation.

”P” POINT MAThread®

Use in difficult applications where point clearance is not an issue. Should also be used with thick stacks of multiple components.

VERY SHORT MAThread®

Use only in applications where point clearance is an issue and angular misalignment is limited. Note that this part is very unlikely to jam if installed at an angular misalignment greater than 8°.