Attributes

Selecting the right fastener involves more than just size and shape—it depends on key attributes that impact performance and durability. Materials determine strength and corrosion resistance, while surface coatings enhance protection as well as assembly friction. Thread types influence fastening security, and head designs affect installation and application.

Below is an overview of the essential attributes that define our fasteners, helping you find the most suitable solution for your needs.

Materials

The predominant material for our products is martensitic steels according to ISO898-1, in the higher strength grades. However, we also offer stainless steel and heat resistant fasteners and have the capability to develop non-ferrous products on request.

Steel in class 8.8, 10.9 and 12.9

Stainless steel in grade A2-70 and A2-80

Surface Coating

Almost all fasteners supplied by Bulten have a surface coating. Surface coatings are primarily applied for corrosion protection and to create a stable assembly friction, but there are also decorative coatings where the corrosion protection is not the primary purpose.

Electroplating

Zink flake

Phosphating

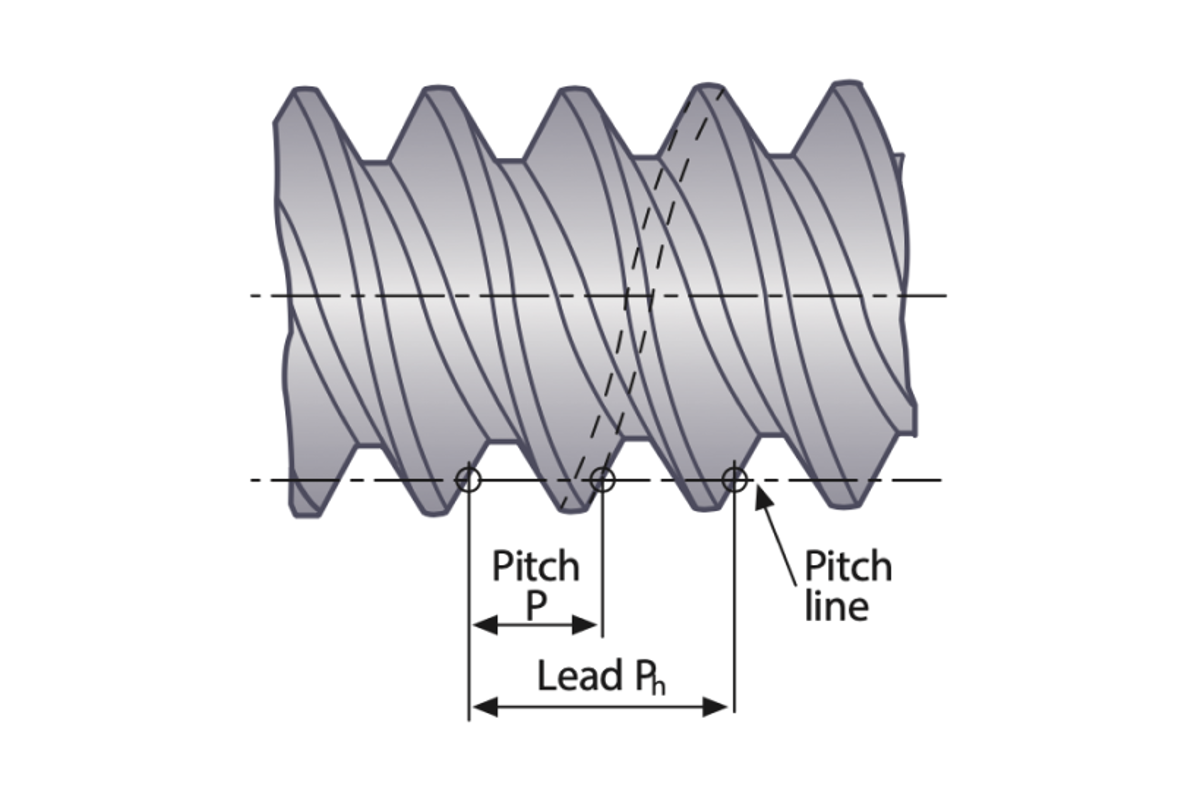

Threads

The ISO metric thread system is the predominant system to which we produce our products. The inch-based unified system still exists, but is slowly being phased out.

M4 to M24

Head Types

The design of a fastener’s head plays a key role in both its performance and application. Head types can impact the ease of installation, security, and accessibility in various environments.

The fastener industry is dominated by a few standardized drive types; hexagon, 12-point and Torx. We offer these drive types in a multitude of head shapes such as flange, cylindrical or pan head designs as well as completely tailor made head designs to customer request.

External drives

Hexagon head

Hexagon head is one of the most common head styles. Two important reference standards are ISO 4014 and ISO 4017.

+ Standardised, good availability

- Relatively small bearing surface

Hexagon head with flange

Hexagon head with flange is the industry standard within Automotive industry. Reference standards are EN 1662, EN 1665, ISO 4162, ISO 15071.

+ Standardised, good availability, large bearing surface

External Torx®, Torx plus®, hexalobular

Reference standards is ISO 10664.

+ Improved drive angle between socket and head, reduced weight of head

External Torx plus® Low Profile Head

+ Reduces head weight with 50 % compared to standard hexagon

Triple square and twelve point head with flange

Requires unique socket.

- Easily rounded off

Internal drives

Cross recess head

Cross recess is used for screws with diameter up to 10 mm. Several variants are available on the market, among those are Ph and Pz most common.

- High risk for bit cam-out

Hexagon socket head

Hexagon socket head cap screws. Reference standard is ISO 4762.

+ Availability and serviceability

- Relatively small bearing surface

Pan head with internal Torx® recess

+ No cam-out tendency, good torque transfer

- Relatively small bearing surface

Pan head with collar and internal Torx® recess.

+ No cam-out tendency, good torque transfer and

large bearing surface

Countersunk head with internal torx® recess

+ No cam-out tendency, good torque transfer